Phone: +91-9050601001, +91-8684980555

Email: info@jaricemill.com

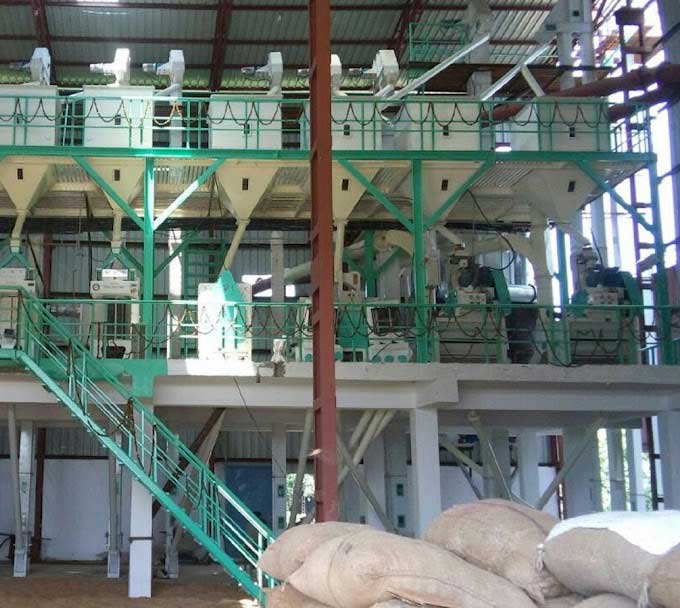

Our Plant expands in the area of 7 acres with shed covered area Approx. 50000 Square Feet & is equipped with ultra-modern Machinery including Automated Dryers, Pre cleaners, Destoners, Precision-Sizers, Paddy Separators, De-Huskers, etc. The plant and its machinery are set up by Satake-Japan which is a world leader in grain processing systems producing a comprehensive range of individual machines, integrated systems, and totally engineered solutions for the processing of rice. Our rice Grading Plant is backed by one of the most advanced technology in grading systems provided by Carter Day-USA. We Provide a Production capacity of 5 Ton/ Hour for Basmati Rice & 3 Ton/ Hour for Non Basmati Rice.

Pre-cleaners from Bühler - Germany and Magnets are used at various stages to ward off foreign material, Packing Machines from Hassia - Germany and Premier Tech - Cronos - Canada ensures best in the class packaging facility and pre-cleaners & we’re one of the few companies in India with dryers from Schmidt Seeger/ Bühler - Germany with the finest technology of the world for paddy continuing drying. Careful attention is paid to ensure that each grain is perfect. Each process is carried out under the eyes of competent

and trained manpower. All the rice that leaves the company premises is of the best quality and is protected during its full journey from when it sprouts in the earth to when it reaches Our Infrastructure is Quite prolific and Includes laboratory equipment like Rice Moisture Tester, Color Sortex Machine, Vernier Length Scale, and Rice Kett Tester

GIPL’s Plant is strategically designed and operated with the aim of improving the relationship between humans, technology involvement and the impact of technology on the environment. Our totally dust free plant ensures that no particles are emitted into the atmosphere.